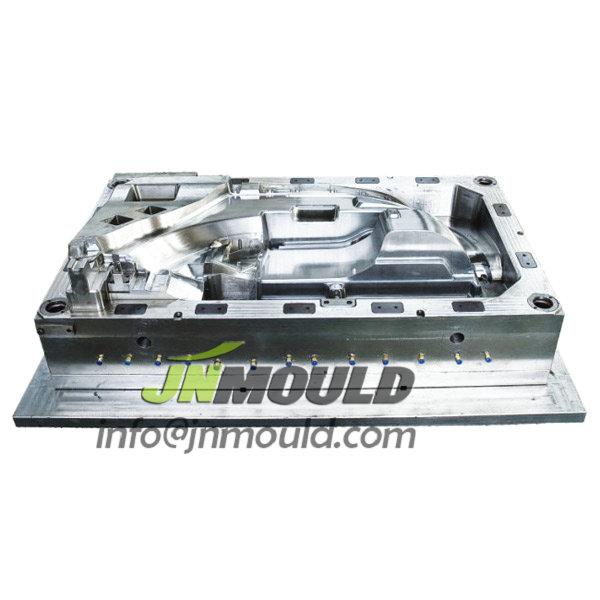

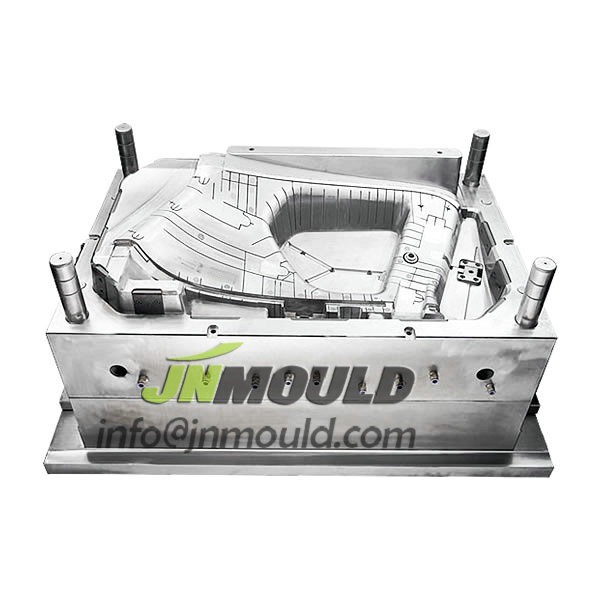

auto door mould

Jnmould has be focusing on the production of auto mold, and auto door mould takes a large share in our company. Generally, there are front auto door mould and rear auto door mould; auto door with speaker mesh and auto door w/o speaker mesh.

The quality request for auto door w/o leather cover and auto door with speaker is higher. The sharp, shrink mark, melting line, scratch and under filled can’t appear on the part of auto door.

We have to consider the following issues during auto door mould designing and manufacturing:

1.The reasonable size of mould base.

2.How to design the cooling system? The water line must be applied as much as possible, and the dia. of water line should be large as much as possible.

3.The location of injection gate. Generally, more than 3 injection points will be used for the auto door mold. The melt line will appear at the two point meeting area.

4.Ensure the ejecting system be safe and reasonable. There are many lifter and ejector for auto door mould, so we have to avoid the sharp caused by the small error during auto door mould manufacturing.

5.Design the reasonable departing line, it will be convenient for auto door mould assembly and manufacturing.

6.Pay attention to the issue of air exhaust when the auto door mould with speaker mesh.

7.Because the auto door mold is large, we have to control all aspects during different step to ensure the quality of door panel mould.